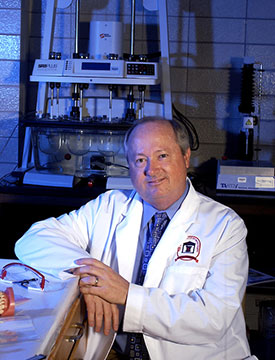

Michael Repka

For as long as civilizations have practiced medicine, people have searched for better, safer ways to deliver drugs. Today’s innovators are working with new technologies to design different kinds of drug-delivery systems, a prime area of research for Michael Repka, chair and professor of pharmaceutics, director of the Pii Center for Pharmaceutical Technology and research professor in the Research Institute of Pharmaceutical Sciences.

Repka is an expert in a technology called hot-melt extrusion, a process that lends itself to developing a wide range of alternative drug delivery systems, from extended release tablets to transdermal patches. Most of Repka’s work is dedicated to oral transmucosal drug delivery, in which dissolving patches are placed in the mouth so that drugs may be absorbed via the oral mucosa—or mouth lining—which is more permeable than skin. A 12-year initial career in dentistry gave Repka unique expertise regarding the oral cavity and an innovative edge when he earned a doctorate in pharmaceutics.

For certain drugs, transmucosal delivery provides a number of advantages. Most notably, drugs delivered via oral mucosa bypass the liver. While a healthy liver acts as a defense against toxins, eliminating anything the body perceives as a threat, that process can also mean the liver lessens or even destroys the efficacy of some medications— known as the “first pass effect.” Transmucosal delivery avoids this problem. Because drugs administered through the oral mucosa skip the first pass effect, they often require lower dosages. If only 25 percent of the regular dose is needed, manufacturers are able to use less of a drug, and patients receive less exposure over long-term regimens.

“You can utilize hot-melt extrusion to improve the bioavailability of drugs,” Repka said. “You can increase the solubility, and therefore, you can increase how much is absorbed into the bloodstream.”

One drug for which oral transmucosal delivery seems to be a particularly promising delivery method is Tetrahydrocannabinol, better known as THC, the primary psychoactive agent in marijuana. When purified, THC resembles a glob of tar, and dissolving it is a challenge.

“THC is a very difficult drug to work with in a lot of ways,” Repka said. “THC is available in the U.S. market in capsules that are swallowed for the treatment of nausea and to stimulate appetite in AIDS patients. The amount of THC absorbed from the intestinal tract from the capsule dosage form is highly variable from person to person. Some people get the correct therapeutic dose without side-effects, others get way too much in their system resulting in the kind of high you would get from smoking marijuana. Others hardly absorb any THC at all.”

Michael Repka

To address this problem, Repka and his team are trying to develop a THC dosage form that will give patients a more consistent blood level. Trying different types of polymers, Repka and his team were able to develop a transmucosal patch that has been studied in rabbit and pig models. They believe an oral mucosal patch is the ideal delivery system for THC and are working with ElSohly Labs Inc. in Oxford on commercial development of the patch.

Besides offering promising results for patients, alternative drug-delivery systems are also valuable to the pharmaceutical industry because of their patent-extending applications. By developing improved delivery systems for drugs that are about to lose patent protection, pharmaceutical manufacturers can secure additional years of patent protection.

Repka’s work also directly benefits his students, whose proficiency in hot-melt extrusion leads them to career opportunities. All students in Repka’s research group receive experience working in hot-melt extrusion, and Repka frequently receives calls from employers seeking graduate students versed in the technique.

“Highly trained pharmaceutical scientists are being trained at the University of Mississippi,” Repka said. “Graduate students who have worked in hot-melt extrusion are highly sought by the pharmaceutical industry and other academic research groups around the world. If they have experience in hot-melt extrusion, they are going to get a job and very quickly. They’re in demand because the technology is still emerging, and the industry needs scientists who understand this unique technology.”

Repka is optimistic that pharmaceutical development and manufacturing companies may one day locate in Mississippi, providing local jobs for graduates.

“That puts us in the driver’s seat for licensing technology and creating high-paying jobs here so that our graduates don’t need to go to the East Coast,” Repka said. “That’s the exciting thing about it—that it’s got the potential to help people here.”